THE COMPANY

A family history that looks to the future

A reference POINT IN ITALY AND BEYOND

The "craft workshop" of the Brodini family was established in 1853 as a workshop for woodworking and metalworking. Since then, commitment, passion, and professionalism have enabled the workshop to analyse and meet market demands, specialising in precision mechanical processing.

Today, the company is a reference point throughout Italy and beyond, capable of fulfilling every request in both the carpentry and mechanical processing sectors.

Meccanica Broter, always in line with the latest industry requirements, utilises advanced machinery and equipment, providing you with a team that is kept up to date through ongoing specialised training courses.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

A STORY OF ACHIEVEMENTS

Since 1853, the story of Meccanica Broter is one of success and triumphs, as well as consistency and great determination.

Many milestones have been achieved, particularly with the construction of the new headquarters in 2011, spanning over 4,000 square metres, of which more than 2,000 are covered. The introduction of modern production systems, the acquisition of CNC machinery, and state-of-the-art software now enable the company to play a leading role in mechanical processing, while also fostering a partnership with clients on both design and technical aspects.

Always ready to take on every request, Meccanica Broter specialises in milling, turning, drilling, boring, and medium-light mechanical carpentry operations.

DESIGN STUDIO

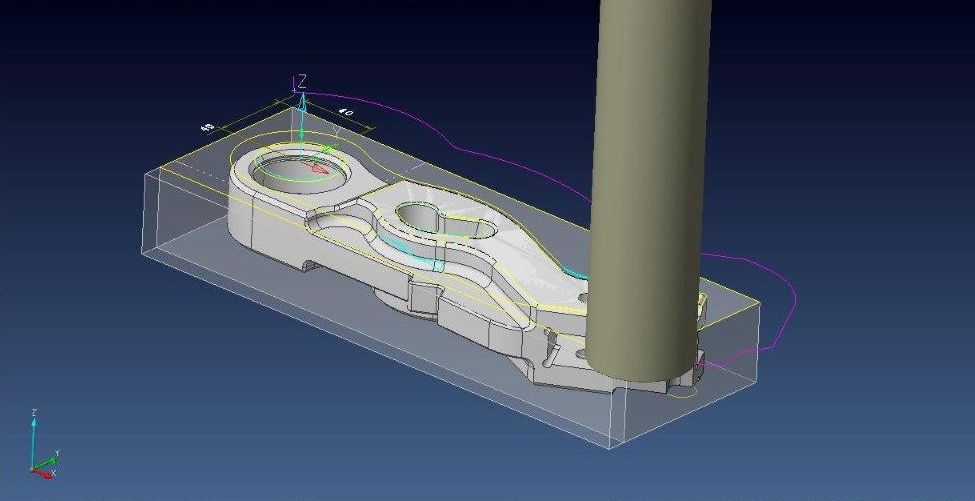

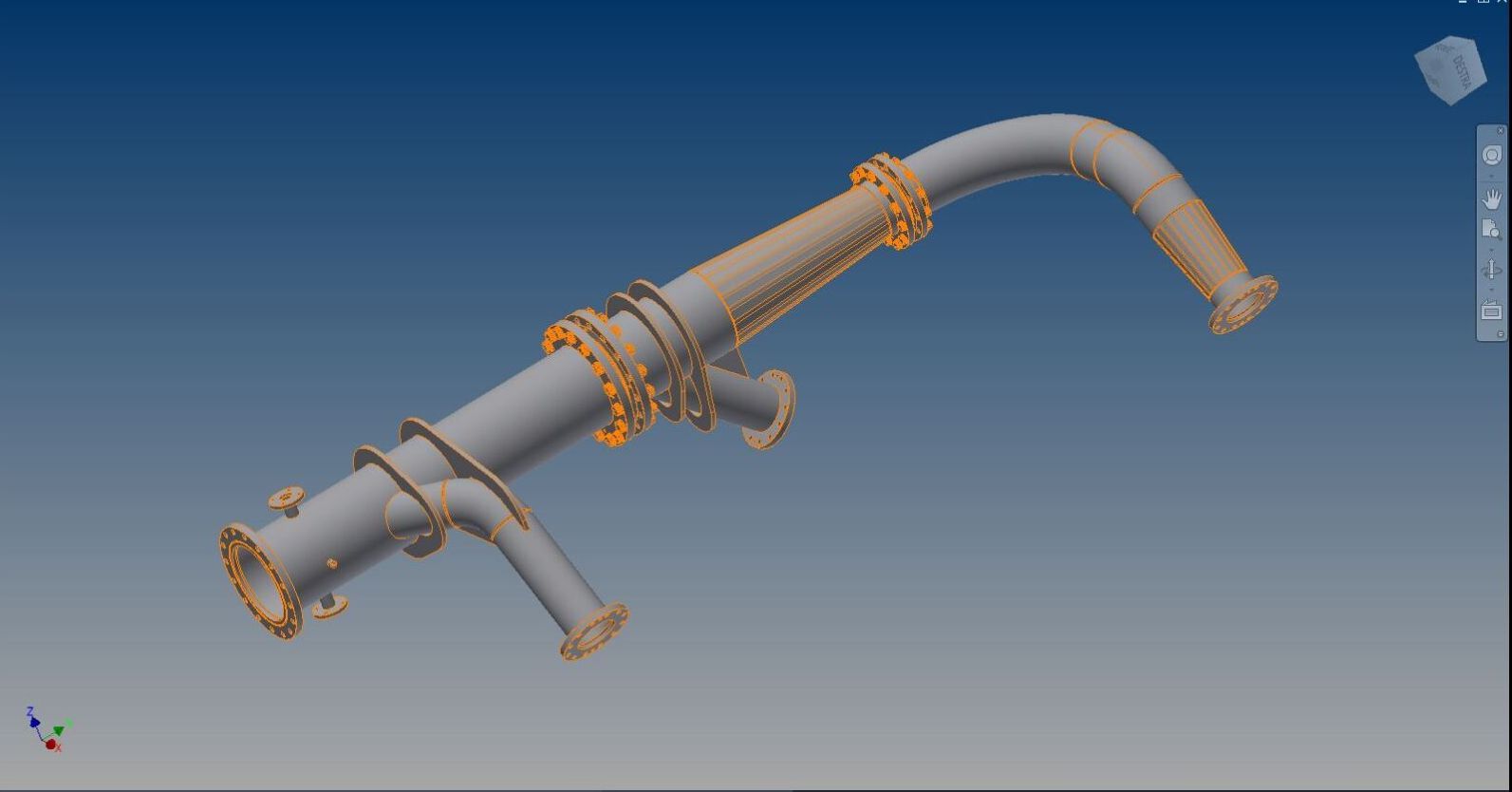

For the past ten years, Meccanica Broter has established a design studio capable of meeting all customer requirements.

The company offers a unique approach and stands out by taking care of every requirement, from the design phase to the delivery of the requested product.

The professionalism of its specialised staff, combined with the use of the best machinery on the market, allows Meccanica Broter to consistently offer the highest quality standards and meticulously executed orders, all aimed at ensuring precision in every job.

Titolo diapositiva

Scrivi qui la tua didascaliaPulsante

COMPREHENSIVE COUNSELLING

Not only precision and mechanical work, the company offers 360° consultancy from the design phase to the delivery of the requested product.

Thanks to advanced CAD and CAM tools, the company produces numerous components for third parties, providing specialised consultancy to reduce production times while ensuring and improving the quality of the finished product.

THE HISTORIC COMPANY OF AZZANO MELLA, OWNED BY THE BRODINI FAMILY

quality and certifications

Always attentive to the quality of its work, the Meccanica Broter workshop in Azzano Mella, in the province of Brescia, obtained the UNI EN ISO 9001:2015 certification in 2007, an important milestone that serves as further evidence of the company's commitment to the highest quality standards.

In addition to the UNI EN ISO certification, great importance is placed on the quality management system, which, for Meccanica Broter, serves as a benchmark for managing production at all stages.

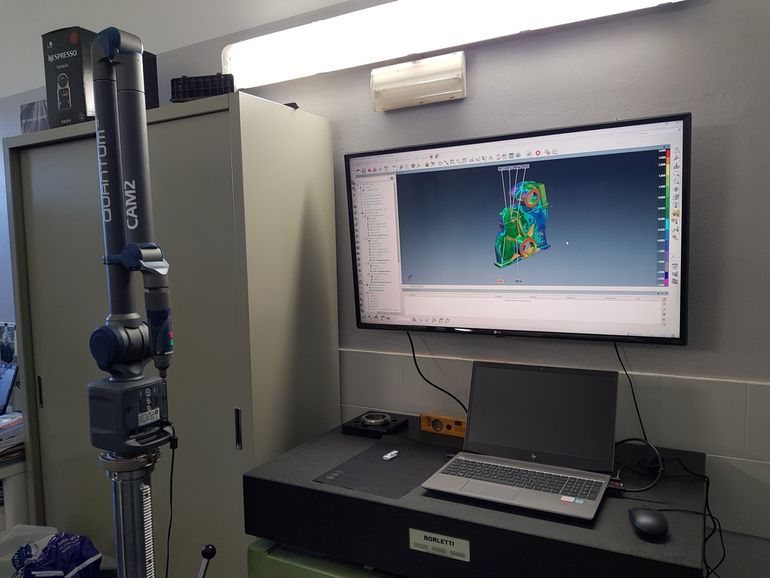

THREE-DIMENSIONAL INSPECTIONS AND CERTIFICATIONS

Renishaw, a company specialising in measurement and motion control systems, has expanded its range of inspection tools with a new system that enables the verification of the alignments and positioning of the rotary axes of machine tools.

The mechanical workshop has implemented this system across multiple machines, allowing technicians to identify and document any alignment and geometry errors on-site that could lead to non-conforming parts and slowdowns in production.

Alongside the UNI EN ISO 9001 certification, this advanced system enables the workshop to guarantee the highest standards of quality, efficiency, and precision, as well as absolute compliance with the required technical specifications.

An additional inspection of the finished piece is conducted using the “Faro arm,” which allows for a check on the dimensions and tolerances of the manufactured part.

REQUEST MORE INFORMATION

Thank you for contacting us.

We will get back to you as soon as possible

An error occurred while sending the message. Please try again later

MECCANICA BROTER DI BRODINI E C. s.n.c

VAT No. 01223850171 | Legal Notes | Privacy and Cookie Policy